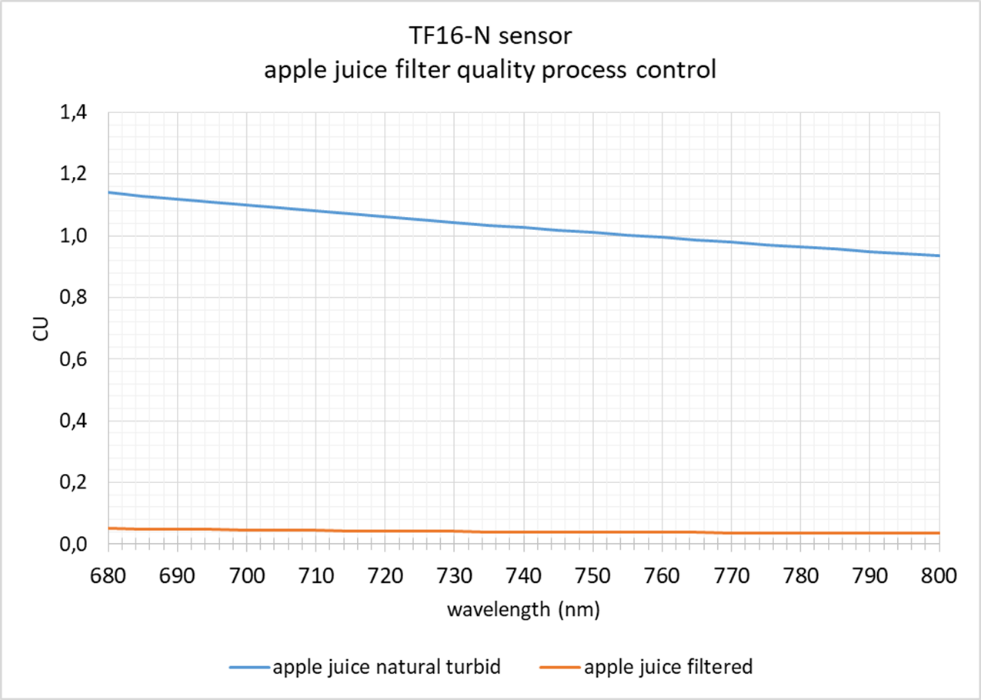

Process control in demanding industrial environments need professional systems which are able to withstand extreme temperatures, pollution and aggressive media to analyze efficiently. Durable materials and technologies are required to guarantee extended longevity of the equipment to measure specific parameters with the highest accuracy and reproducibility. Low level concentrations of particles in ppm or even ppb must be quickly detected without any interference. The whole system must be designed for specific cleaning procedures like CIP and disinfection cycles, as well as minimal servicing and maintenance. Most important is the tailor-made measurement technique for the most effective, reliable and error free results. Depending on the particles to detect the measurement angle of 0° for direct and 11° or 90° for scattered light allows for differentiating normal and non-normal constituents, as well as eliminating the influence of color.

Turbidity Application

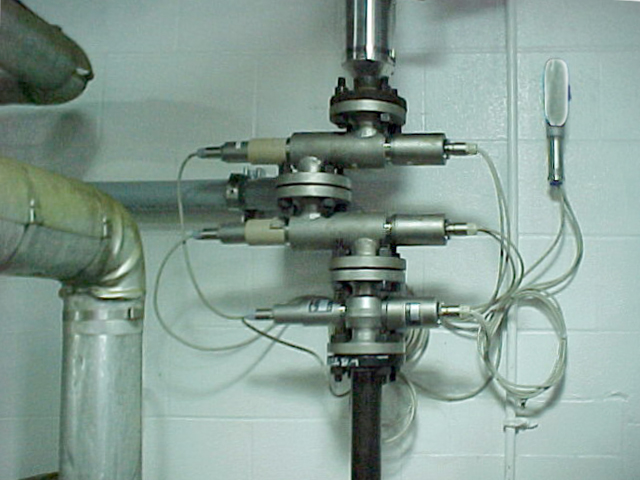

Flexible installation of turbidity sensors regarding dimensions and materials is mandatory in industrial processes. Reliable converters are used for data collection from connected sensors and manage the data transmission to the PLC using different communication methods. User-friendly software supports quick setup, adjustment to local needs and avoids errors thanks to full text menus. Alarms can be individually configured for safe processes.

Turbidity system applications include turbidity detection as in a solids break-out, or a carry-over of an undesirable constituent, separation and filtration monitoring and control, solids concentration, for dosing or biomass growth, interface between product phases, water quality, wastewater BOD, blending control of cloudifier agents, haze control, concentration, clarity and stability assessments and much more.

Turbidity System

Turbidity meters measure an optical property of liquids caused by particles and colloids in a liquid. optek analyzers employ advanced techniques to suppress optical effects not caused by particles in the liquid, such as color, signal noise, stray light, or other environmental influences. optek’s turbidity systems are precise and repeatable, automate processes, provide tremendous payback opportunities by improving process efficiencies and reducing product losses and waste. optek turbidity systems are designed to meet these objectives in a rugged, stable, reliable, and low maintenance package, designed for continuous use in a variety of industrial, sanitary, and biotech applications. ROI's of 6 months or less are common, and in virtually all cases, optek turbidity systems will have an immediate impact on bottom line production costs.