Blancher Make-up Water Monitoring and Control

For most processors, the blanching process is by far the largest consumer of water and energy. In some operations the blanching process was reported to consume more than 50% of the plant's overall energy usage and more than 30% of the plant's overall water consumption. This means that even small improvements to the blanching process could dramatically improve the operation's bottom line.

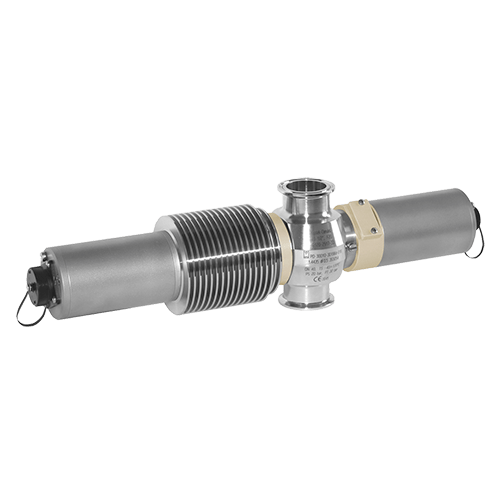

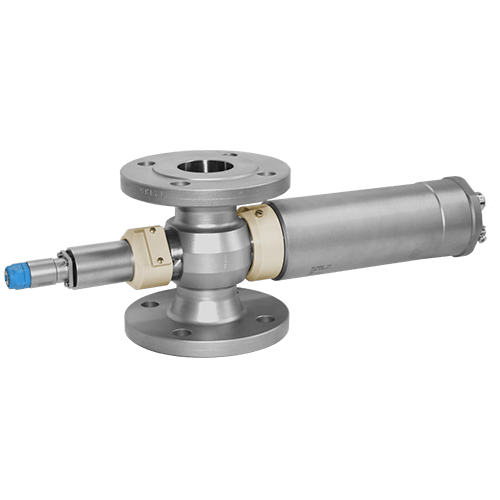

optek equipment used in blancher make-up water monitoring

UV absorption sensors provide a unique means of monitoring and controlling blancher water quality. Unlike turbidimeters which monitor only suspended solids, or refractometers which see only dissolved solids, UV sensors are sensitive to both suspended and dissolved solids in the blancher water. The sensor provides a reliable, real-time indication of overall blancher water quality with a minimum of maintenance.

Blancher Make-up Water Monitoring and Control Benefits

- Reduce Water Usage

- Reduce Energy Consumption

- Reduce Wastewater Volumes

- Reduce Product Losses

- Improve Product Quality

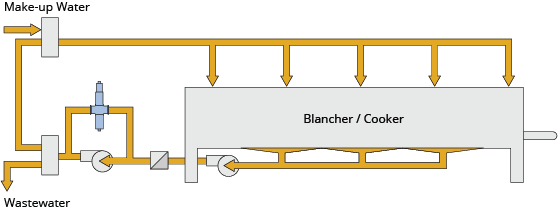

The diagram shows a simple schematic of a typical blancher installation. The optek absorption sensor is installed in a bypass line that runs from the discharge side of the recirculation pump back to the suction side of the pump.

The high-pressure differential insures a high flow velocity, minimizing the risk of solids build up in the sample line. Installation after the screen helps eliminates the larger material that could lead to plugging in the sensor or sample line.

The optek C4000 converter sends a 4-20 mA signal to the plant control system. This signal is proportional to the level of dissolved and suspended solids in the blancher water. Based on this signal, a PID control loop can be implemented to control make-up water addition to achieve a consistent blancher water quality.

Blancher/Cooker Make-up Water Monitoring Summary

Installing an optek AF45 or AF46 sensor on your blancher enables automatic control of blancher make-up water addition and ensures a consistent blancher water quality. Optimizing the rate of fresh water addition to the blancher will help your plant to reduce water usage, reduce energy consumption, reduce wastewater volumes and reduce product losses.

The purchase and installation of one optek sensor per blancher is easily justifiable as the substantial loss reductions provide an extremely fast return-on-investment (ROI). Further benefits obtained by improving the blanching process control are improvements in consistency of color, texture, and perhaps even taste of the final product.

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.