Off the shelf or customized to your specific needs

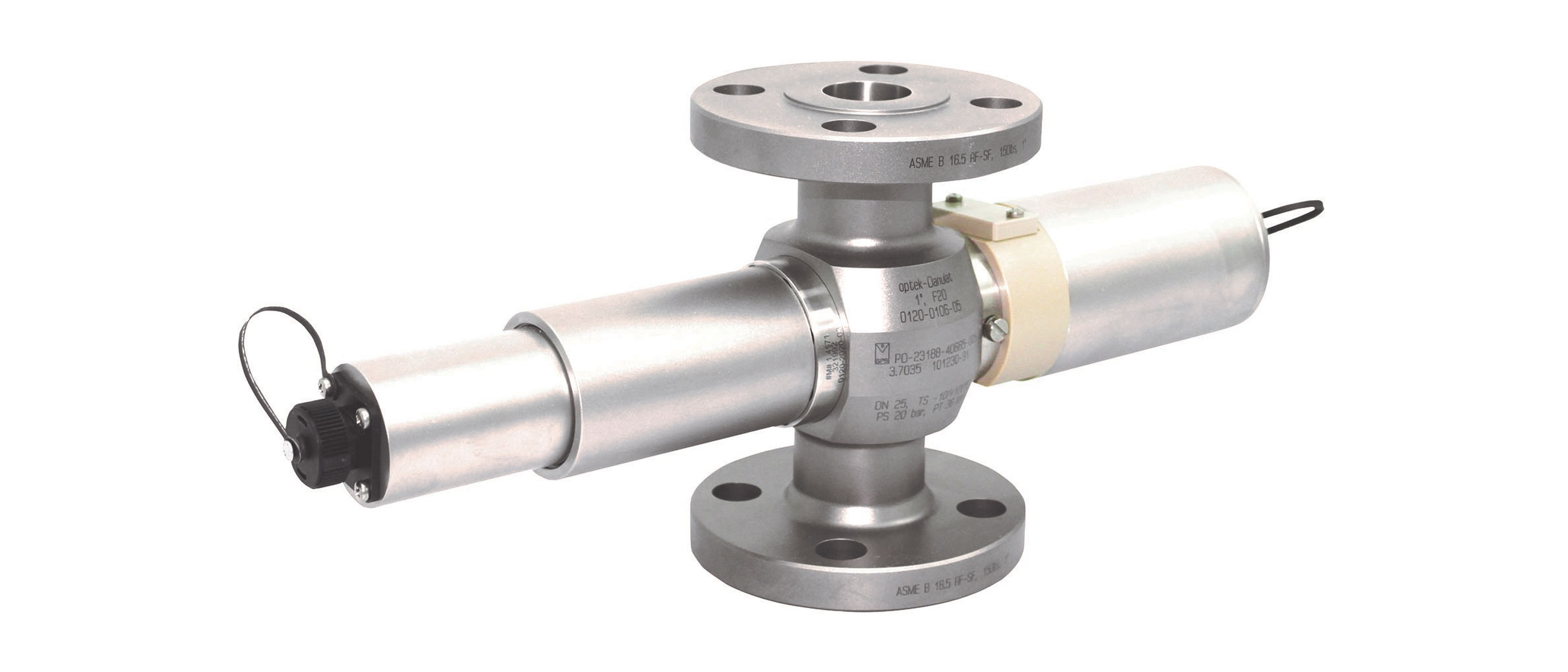

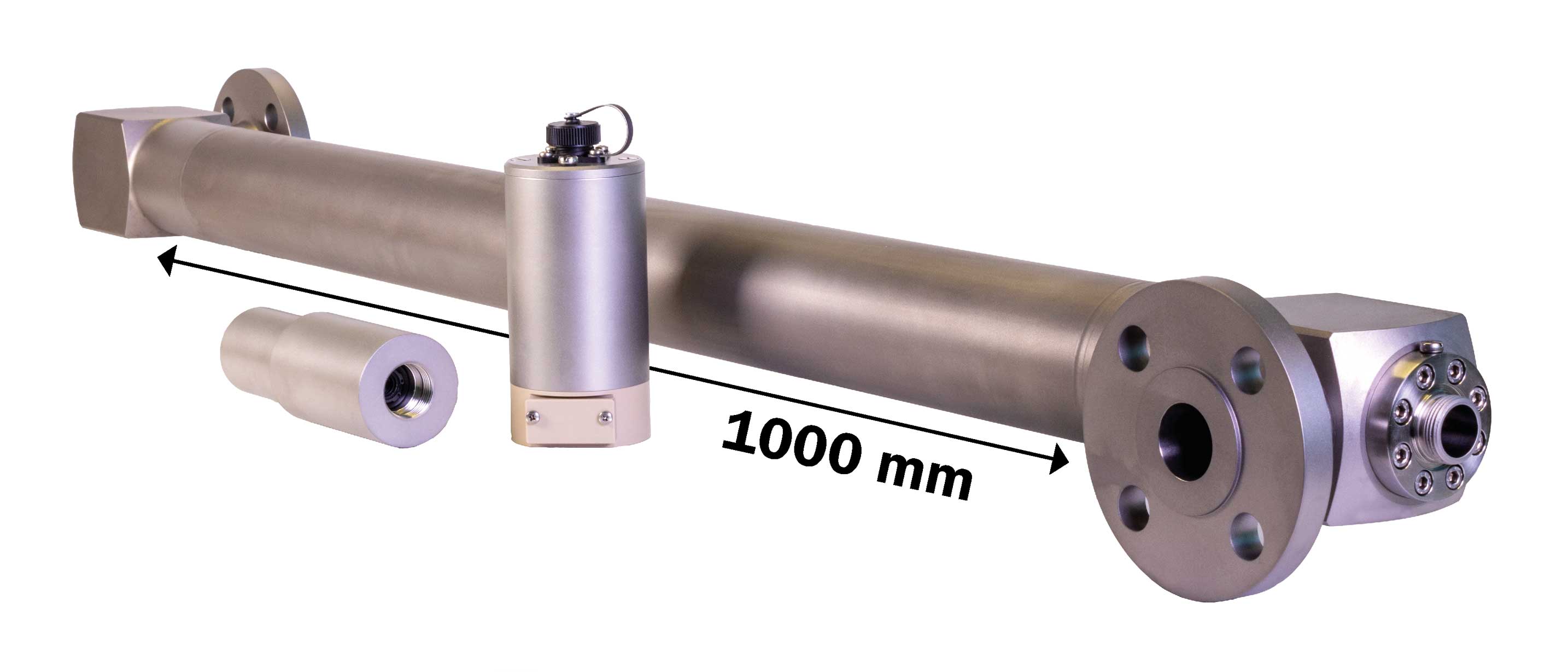

The armature - assembled sensor body - is the central component of an inline photometer. We have already designed more than 1000 different sensor bodies and more than 50 types are always on stock. All optek inline sensor bodies are made from high quality materials and are machined with extreme precision. The quality-tested manufacturing tolerances allow optical path lengths of up to 1000 mm, for which the accuracy of the incoming and outgoing light beam is ensured by testing a laser-based coaxiality tolerance test to the reference axis. To cover a wide spectrum of different process conditions, optek sensor bodies can be manufactured from various materials (also for aggressive chemicals or with NACE MR 0175) and adapted with regards to:

- process connections (DIN, EN, ISO, ANSI / ASME (BPE), JIS)

- line sizes

- optical path lengths (OPL)

- pressure ratings (incl. high pressure variants)

- window materials

- required surface roughness

- gaskets and sealing surfaces

The sterile optimized biotech line (stock item) fulfills all biopharmaceutical process requirements. I.e., all biotech sensor bodies

- are solid block manufactured (no welding seams and hence no potential for pits or inclusion)

- are made of high quality DIN 1.4435 (AISI 316 L) with a certified delta-ferrite (δ-FE) content of less than 0.5 % to fulfill the material requirement of Basler Norm (BN2) for corrosion resistance.

- have a CIP-friendly design without any cavities oder deadlegs to achieve a superior cleanability

- have sanitary Tri-Clamp® process connections

- have superior physical and chemical resistant sapphire windows with a biotech optimized design regarding minimized seal gaps for CIP cleanibility and extremely low mechanical tolerances for a precise OPL

- have certified electro-polished surfaces with Ra < 0,4 µm for all wetted parts to prevent bacterial adhesion and thus cross contamination with pathogens

With all those features for superior cleanibility and sterility of our biotech line we conform to the 3-A and ASME BPE sanitary standard.

Our modular and compact (minimized hold-up volume) design of all sensor bodies allows universal usage for all optek sensor adaptations (AF / TF / DTF / CF / ACF / PF). Different window rings and different window lengths and materials are possible for customer specific measurement requirements. An easy window maintenance is also advantageous for media causing fouling.

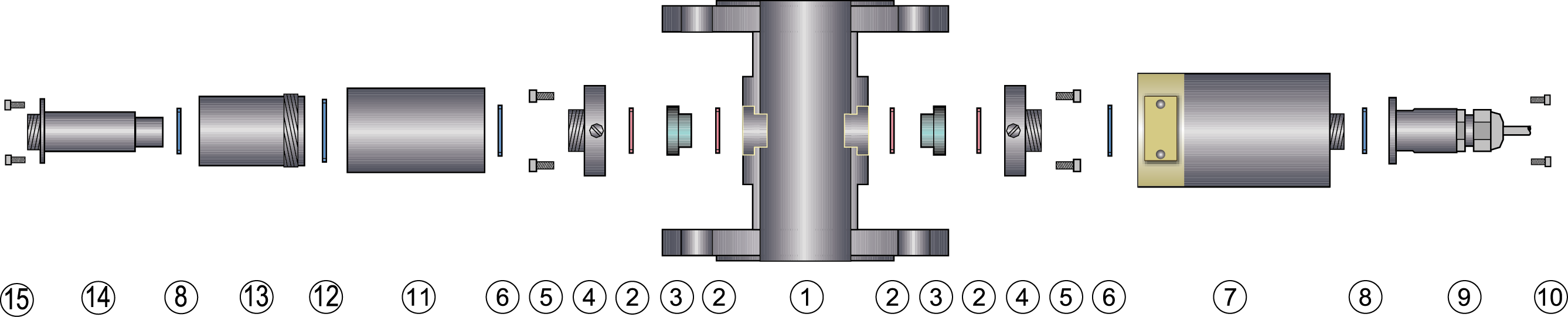

Example Exploded View – Model AF26-VB:

- Sensor body 1/8 in. to 6 in. (DN 6 to DN 150)

- O-rings (EPDM, Viton®, Kalrez® etc.)

- Windows (Sapphire, Pyrex®)

- Window ring M24 (1.4571 / 316 Ti)

- 8 Screws (M5 x 12) with lock washer

- O-ring (Viton®)

- Detector assembly AF26-HT-VB

- O-ring (EPDM, Viton®, Kalrez® etc.)

- SS-plug protection

- 4 Screws (M3 x 6)

- Lamp adapter AF26 incl. optics module AF

- O-ring 31,47 x 1,78 mm

- Optical housing OH06

- Lamp module AF26

- 4 Screws (M3 x 6)

As an ISO 9001:2015 certified manufacturer a complete documentation and traceability of all armatures are available with inspection certificates 3.1 according to EN 10204 including pressure test data and material certificates of the metal heat analysis (exclusion of material confusion) for all materials in contact with process media. optek’s quality assurance system is certified for the manufacturing of pressure equipment according to the current directive 2014/68/EU and the rules of AD 2000-Merkblatt HP0 / A4. 3D-STEP-Files for digital plant planning are available on request.

Our design experience for your application

We are able to supply special connections on request to fulfill customer needs. Following is a list of our specification range as well as the extensive variety of already realized process connections and standards. Furthermore, various process connections according to factory standard e.g., Neumo Bioconnect®, Tri-Clover Tri-Clamps®, Swagelok® or GEA Tuchenhagen Varinline® are already realized. If yours is not listed yet, contact our product specialists for support.

Sensor body specification range |

|

|---|---|

| Material EN 10020 (AISI) | Stainless steel 1.4435 (316L), 1.4539 (904 L), 1.4571 (316 Ti), 1.4462 (318 LN), Titanium 3.7035 (Ti-Grade 2), Hastelloy 2.4602 (Alloy C-22), ... others on request |

| Line size | 1/8 in. to 6 in. (DN06 to DN150) |

| Process connections | Flanges (ASME B 16.5, DIN 263x, EN 1092-1, JIS B 2239, DIN 11864-2) Female threads (ASME B 1.20.1, ISO 228-1) Sanitary threads (DIN 11851, DIN 11864-1) Clamps (DIN 11864-3, DIN 32676, ISO 2852) Tube ends (ASME B 36.19, BS 4825-1, DIN 11850, ISO 1127) … others on request |

| Process pressure | 0 to 100 bar (0 to 1450 psi) and high pressure variants up to 200 bar (2901 psi) depending on process connections, materials and design |

| Windows | 1-Pyrex®, 2-Sapphire, 3-Sapphire Biotech |

| Window gaskets | Silicone (FDA, USP Class VI), Viton® (FDA, USP Class VI), Viton® - FEP (FDA, USP Class VI), EPDM (FDA, USP Class VI), Kalrez® 6230 (FDA, USP Class VI), Kalrez® 4079 ... others on request |

| OPL | 1-1000 mm |

| Surface (wetted): | N5: Ra < 0.4 μm (16 µinch) N6: Ra < 0.8 μm (32 µinch) N7: Ra < 1.6 μm (63 µinch) for plastics |

| For variations and details see separate sensor body datasheet | |

Probe adapter ports

Our color, turbidity, concentration and conductivity probes (AS / ASD / CS / ACS) for the direct installation into process lines and vessels - like fermenter or bioreactors - are available with various weld-in ports or adapter ports (Varinline® / Clamps) made of high-quality bulk material DIN 1.4435 (AISI 316 L). optek`s design is optimized for cleanability and sterility and is combined with precise mechanical tolerances for flush and pocket-free installations with tank walls and pipelines. The design allows the replacement of probes at any time. For maintenace activities unused process ports are closed with a sealing flange.