Fuel Analysis: Free Water in Refined Fuels

Refined Fuels AnalysisFuel analysis is a very important part of the refining process. By continuously monitoring free water and suspended solids in refined fuels, operators can immediately detect inefficiencies or failures in filters, coalescers or separators and identify the presence of possible contamination from other sources.

optek Products used in Detecting Water in Fuels

These hydrocarbon streams can be monitored in real-time under process conditions to determine if and how much free water is present, down to the ppm levels. This allows operators a unique ability to monitor product manufacture, increase product quality, and reduce critical refueling with contaminated product.

Typical Measuring Ranges:

- 0 - 15 ppm for Jet Fuel

- 0 - 50 ppm for Gasoline

- 0 - 100 ppm for Diesel

Dual Channel Scattered Light Free Water Monitoring

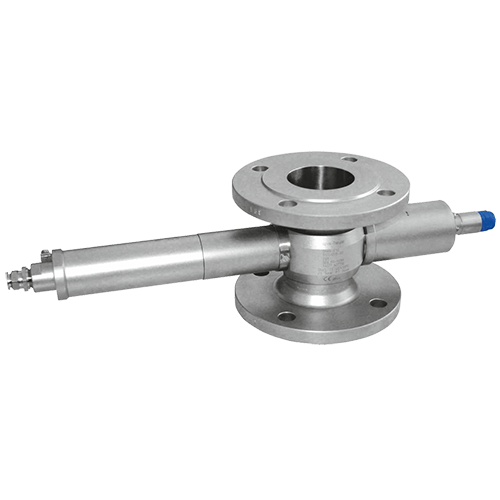

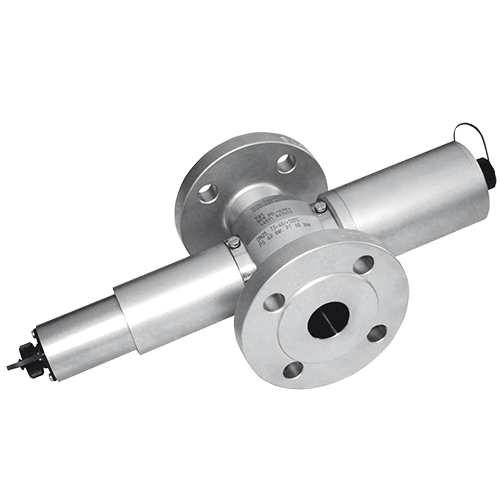

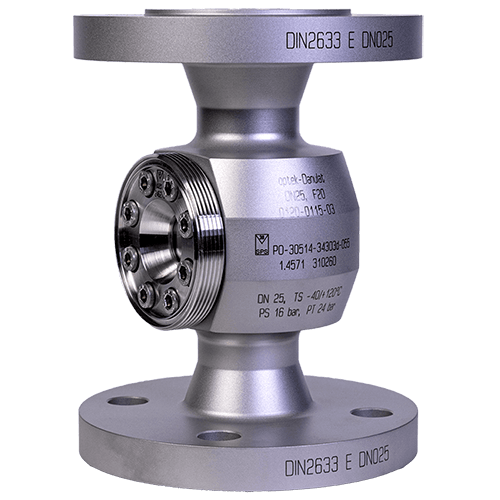

Quantifying the free water content in refined fuels down to low ppm levels is essential. The optek TF-16-N Scattered light sensor uses light in the Near Infrared (NIR) range which is unaffected by color or color changes. Since free water droplets in hydrocarbons tend to be spherical, they scatter light very efficiently, giving a high degree of consistency when determining how much free water is present in the hydrocarbon.

optek TF16-EX-N Scattered Light Dual Channel Turbidity Sensor

Water in Jet Fuel Detection

Free water in jet fuel comes from numerous different sources. Nominal limits for free water in jet fuel are typically in the range from 0-15 ppm (DE) while other fuels may tolerate larger ranges. An optek TF16-N scattered light turbidity sensor will immediately detect these low level contaminations. This important inline measurement is accomplished in real-time and designed for harsh and hazardous area classifications.

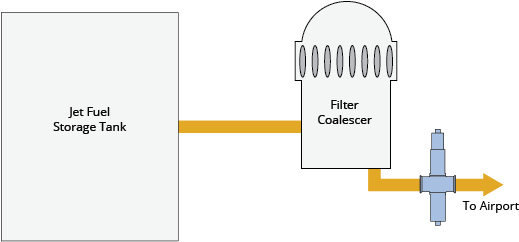

Fuel Filtering/Coalescing Contamination

Water and suspended solids are removed during the production, transportation and loading of fuel. Despite these process controls, potential contamination sources still exist. An optek TF16-N scattered light turbidity sensor installed after a filter or coalescer immediately detects a failure or filter break. Contaminated fuel can then be diverted into a holding tank for further processing while uncontaminated fuel is moved down the process.

Typical Applications

- Monitor free water content in refined product cuts off the CDU (crude distillation unit)

- Monitor free water in transportation fuels (airport refueling, distribution terminals, military refueling skids)

- Monitor free water in lube oils

- Monitor free water in bunker oils onboard ships

- Monitor free water content during product manufacture (cyclohexane, isopropylene etc.)

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.