Introduction

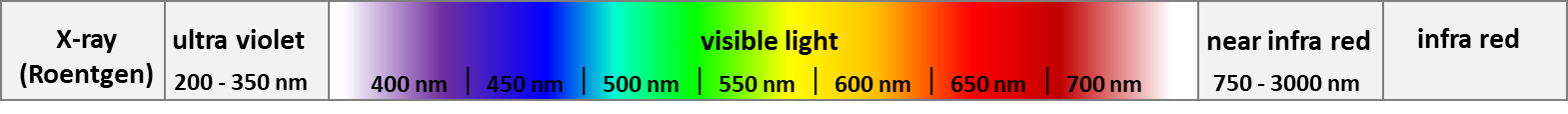

Color measurement is originally based on comparison to existing color standards, like real examples, tables etc. The human eye was the very individual indicator for a color e.g., already being green or still being yellowish. A reproducible distinction of colors is impossible, if it is not measured under defined conditions. The visible wavelength range is around 380 to 740 nm, whereas UV and NIR cannot be seen by human eyes.

There are several color definitions, such as RGB (additive coloring) or CMYK(subtractive coloring). Beside the color itself there are parameters describing differences: brightness, saturation and gloss.

For instance, for safety and traffic signs the DIN EN ISO 7010 gives a definition of colors to be used. There are many norms with color definitions for almost any product. However, if in the industry two products should be compared to have 100% the same color, it is obvious that a precision measurement technique is needed to check for reproducible colors. The quality control is one important use case for color measurement.

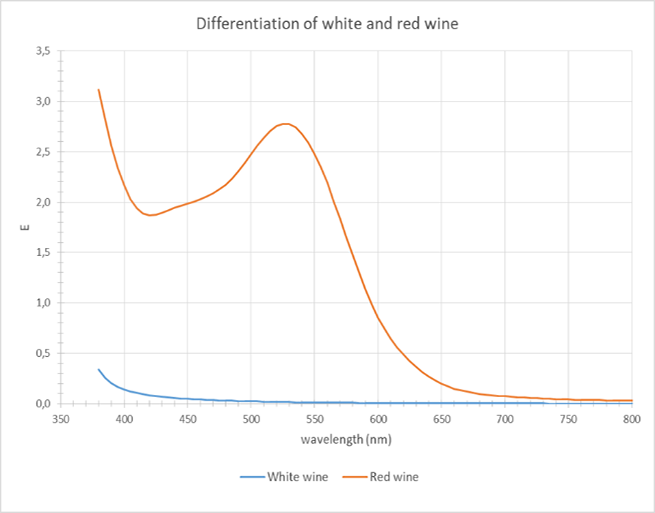

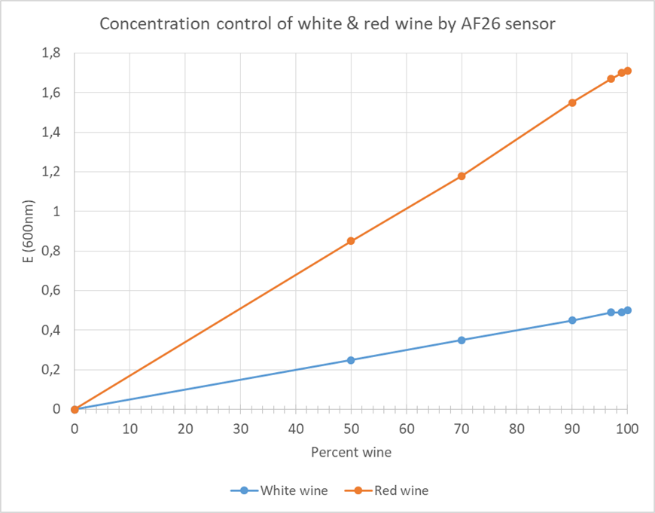

If a cleaning step (CIP) is started, a color sensor can quickly identify, if colored sample is still present in the production line, or if the pipes and vessels are clean. Product differentiation is another example:

Figures 1 & 2: product differentiation by color measurement and concentration control

Selection of the right color measurement system

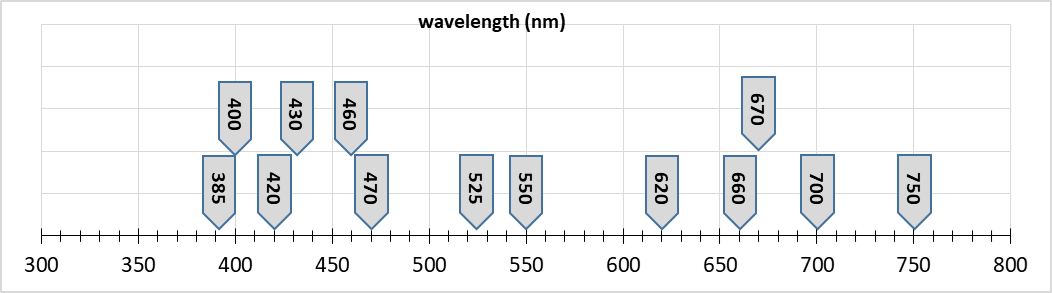

If the sample behaviour is known, the user selects the wavelength to configure the color sensor. If it is not clear which wavelength to select, the user should do a VIS wavelength scan with a lab spectrophotometer. From the spectra one can select the best wavelength to differentiate the sample from other parts. optek’s color sensors can be equipped with specific wavelengths as shown in the following table:

Figure 3: optek VIS color sensors, available wavelengths

Color scales and definitions

Saybolt color scale

To determine if fuel, e.g., kerosene, gasoline, diesel, is contaminated or has degraded during storage time, a specific color measurement test, using the Saybolt color scale (ASTM D156, ASTM D6045), can be performed. Both ASTM methods are off-line methods. The Saybolt color scale range is from +30 (clear water / white) to -16 (dark yellow). ASTM D 1500 also describes the color testing of petroleum products.

APHA Scale (American Public Health Association)

To evaluate pollution levels in wastewater and for drinking water control, a specific color scale is used, called Pt/Co scale, APHA-Hazen Scale, or APHA Scale. Generally it is described in ASTM D 1209 for the comparison of yellow sample color intensity. The APHA color scale range is from 0 to 500 in ppm (parts per million) platinum cobalt to distilled water, what is the zero point (also called white water). The test for APHA color is performed in chemical, pharmaceutical, petroleum und plastic industries, as well as in beverage production.

Gardner Color

This color scale describing the yellowness of transparent liquids is from 1 to 18, where 1 is light yellow and 18 is a dark brown. It was originally designed for testing resins, fatty acids, varnishes and drying oils using liquid color standards. ASTM D 1544 describes glass filters to compare with yellow colored liquids and ASTM D6045 defines the correlation to the Gardner color scale. The relationship to CIE led finally to ASTM D1544, Standard Test Method for Color of Transparent Liquids (Gardner Color Scale). The spectrophotometer method using a 10 mm path length for transmission measurement is described in ASTM D6166, Standard Test Method for Color of Naval Stores and Related Products.

CIELAB color space (Commission Internationale d`Eclairage, CIE)

The L*a*b* color space (CIELAB, CIEL*a*b*, Lab colors) describes all visible colors, using a three dimensional space, where brightness L* is vertically positioned on the color layer (a*, b*). This color scale is described in EN ISO 11664-4 „Colorimetry -- Part 4: CIE 1976 L*a*b* Color space“. The most important advantages are the test device independent color evaluation under defined and reproducible standard conditions.

EBC (European Brewery Convention)

For product and production control beer brewers have to measure color intensity and turbidity (haze) in EBC units, roughly darkness of a beer or wort, as well as quantifying turbidity (haze) of beer. The Standard Reference Method (SRM) and European Brewery Convention (EBC) methods have mainly replaced the "Degrees Lovibond" or "°L" scale, with SRM results being approximately equal to °L. The Standard Reference Method describes the use of a spectrophotometer or photometer measuring the attenuation of light at 430 nm wavelength, (blue).

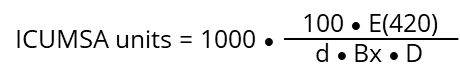

ICUMSA (International Commission for Uniform Methods of Sugar Analysis)

With the ICUMSA methods book detailed instructions are given to analyse all types of sugars, molasses etc. For color evaluation the extinction at 420 nm wavelength is controlled at defined optical path length. Pure, white sugar absorbing less light (value 45) compared to brown sugar at value 1000 for high absorption. For the calculation of the ICUMSA value additional parameters must be tested, such as density, refraction index.

- E(420): extinction measured at 420 nm

- d: optical path length (cm)

- D: density

- Bx: refraction index (e.g. BRIX)

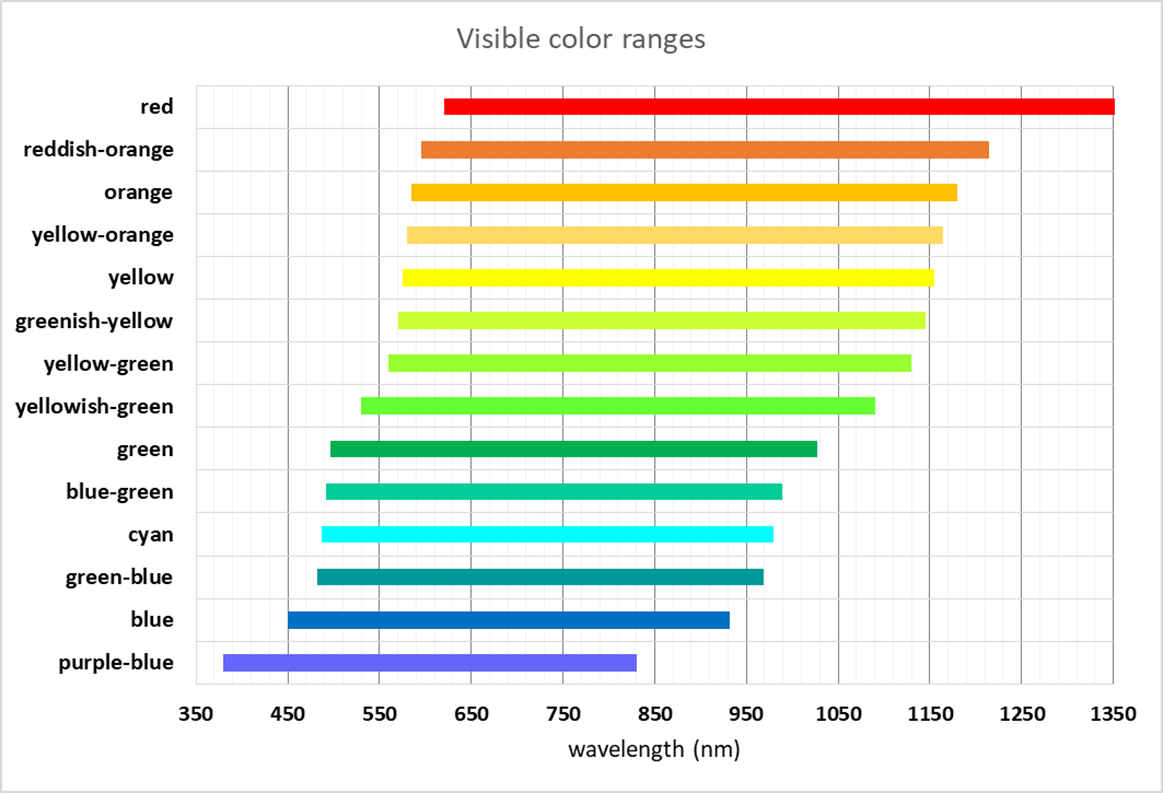

VIS color ranges

Figure 4: Individual wavelength ranges per VIS color.

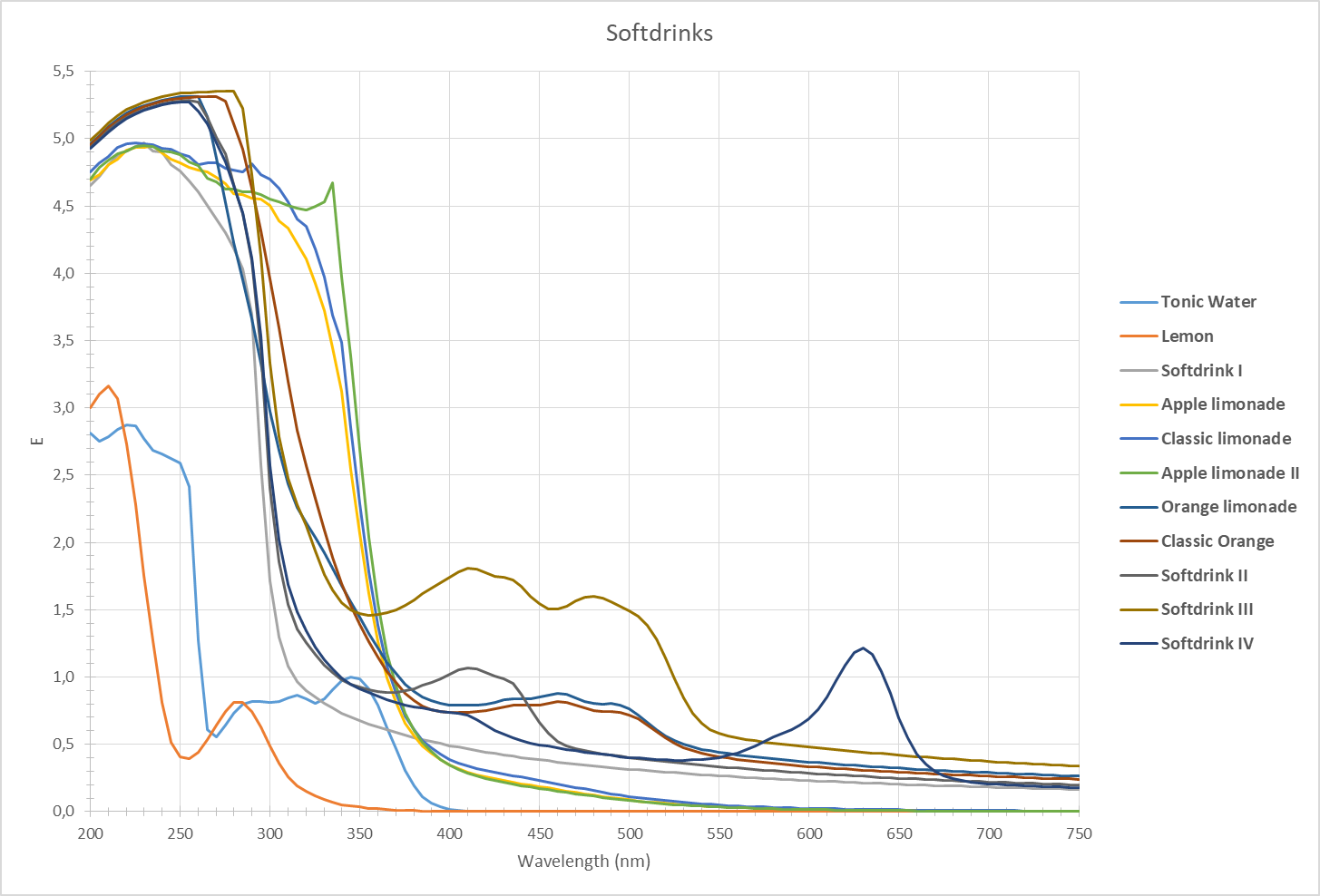

Figure 5: Example of a mixture of beverages in the UV-VIS range.