Saybolt Color Analyzer

Inline Saybolt color scale measurements

optek’s Saybolt color analyzer is a dual wavelength light absorption sensor. Operationally, the sensor passes a white light beam through the stream to be monitored, where light absorbance is measured at two distinct wavelengths. The measuring wavelength is set to focus on or near the peak absorbance point of the “yellowness” curve, while the secondary wavelength is chosen to compensate for any influence due to light scattering (window fouling, particulate, immiscible fluids, gas bubbles, etc.). Together, the sensor yields a repeatable and reliable true color number without any sample conditioning.

What is the Saybolt Color Scale and how is it used?

For many years, the Saybolt color test was used as a visual determination of the relative quality of gasolines, diesel & jet fuels, naphtha and other light petroleum products. While the Saybolt color test was originally done by comparing a product sample to a standard color chart, advances in inline process photometry enables Saybolt color to be monitored in real-time under process conditions. This ability allows crude oil refiners, natural gas processors and pipeline owners an opportunity to monitor/control manufacturing process parameters where it couldn’t be done before; and as a result, a real time opportunity to increase product quality, control product manufacture, and monitor product transfer.

optek inline Saybolt color analyzer reading 29.8 Saybolt while measuring .11 haze in real-time

Saybolt color scale:

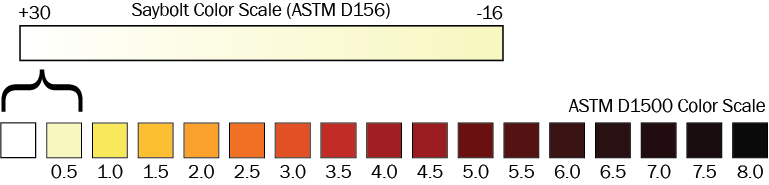

- ASTM D156 defines the Saybolt color scale (+30 to -16 Saybolt)

- Used for determining the color of:

- Gasoline

- Jet fuel

- Kerosene

- Naphtha

- NGL (Natural Gas Liquids)

In short, +30 is water clear, with the Saybolt values decreasing as the color gets more and more yellow.

ASTM D1500 color scale:

- ASTM D1500 defines the ASTM color scale (0.5 to 8.0 ASTM)

- Used for determining the color of:

- Lube oils

- Heating oils

- Diesel fuel oils

In short, -16 Saybolt approximately equals 0.5 ASTM, and from this point the ASTM values increase as the color gets more and more red.

Additional Haze measurement detects product contaminants

Saybolt color is measured in product streams that are typically free of any contaminant. But sometimes a leak can cause other substances like water or amines to enter the product stream, that will turn the product cloudy. By observing just the color signal, operators wouldn’t know that water or amines are present. Using the Saybolt color analyzer’s secondary wavelength such contaminations can be detected in real time. When used in this way, the instrument comes with two sensors in one, a color- and a haze monitor.

Two samples measuring 25 Saybolt; The left sample has trace amounts of amines causing haze / cloudy look.

What makes optek's Saybolt color systems better?

The complete Saybolt Color Analyzer uses an optek C4422-Ex transmitter, an AF26-Ex-VB sensor and stainless steel process connection. Together, this Saybolt color analyzer system offers the following advantages:

- Saybolt color measurements without any sample handling / conditioning

- Color measurements independent of flow rate / flow velocity, density or viscosity

- Can accommodate two independent measurement points on one C4422-Ex transmitter

- According to ATEX: Can be installed in Zone 1 (EPL, "Gb") or in Zone 2 (EPL, "Gc"). Conform to IECEx.

According to FM: Can be installed in Class 1, Division 1 or Class 1, Division 2 areas - Can accommodate high temperatures and pressures (refer to the analyzer's Technical Data

- Independent monitoring of the reference wavelength, giving a real-time indication of haze / turbidity / opacity

- System comes with a NIST traceable validation / calibration filter allowing for an online check of sensor performance

- Utilizes a tungsten filament lamp ensuring long lamp life and consistent emissivity

- User friendly, menu driven interface for easy operation

optek inline Saybolt color analyzer made for hazardous process conditions with high pressures and temperatures.

Realworld examples of measuring Saybolt color inline

- Color verification at NGL custody transfer points (LACT skids)

- Color of refined transportation fuels

- Product quality/color verification at lube oil process and bottling plants

- Detect crude carryover in refined product cuts off CDU (crude distillation unit)

- Product to product interface detection in refined fuels distribution pipelines

- Heat exchanger leak detection

- Monitor sulphur removal efficiency at diesel fuel desulphurization units

- Monitor product quality at NGL truck unloading facilities

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.