Monitoring High Protein Concentrations Downstream

Example: Tangential Flow Filtration

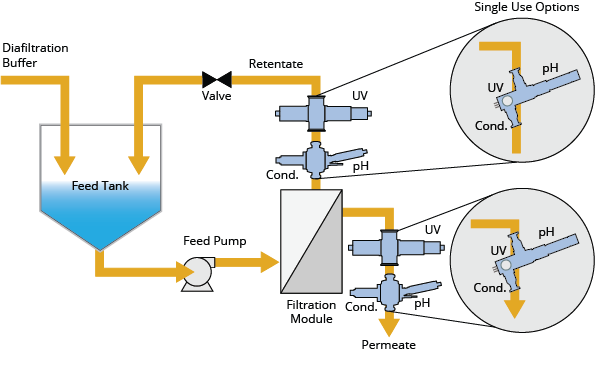

Most of today’s biopharmaceutical downstream processing involve Tangential Flow Filtration (TFF), also known as Crossflow Filtration or UF/DF (Ultrafiltration/Diafiltration), in which the feed stream runs parallel to the membrane through the TFF Filtration Module, where a certain portion passes through the membrane as “Permeate” while the remaining portion is recirculated back to the Feed Tank as Retentate”. Besides the Feed Pump, a throttling valve in the Retentate loop serves as control for creating back pressure to regulate the flow of the Permeate through the membrane.

optek Products used in TFF –UF/DF Retentate Monitoring for High Protein Concentration Targets

Common Tangential Flow Filtration (TFF) Applications

- Concentrating proteins or nucleic acids (e.g. RNA, DNA or oligonucleotides) to a high target concentration by removing liquid from the process stream

- Desalting proteins or nucleic acids

- Exchanging solvents or buffers between chromatography steps

- Fractionating these biomolecules by their molecular size or weight

Challenges of measuring High Protein Concentrations in Real-Time

For many years, it has been industry practice to gather process samples from product streams and measure them off-line, diluted to low concentrations, in the laboratory. However, due to increasingly higher protein concentrations in TFF and other downstream processes, the general perception has been that conventional process UV absorbance measurements were no longer capable of tracking proteins at these concentration levels, even when using the smallest optical path lengths.

This off-line process takes time and can delay the entire TFF process from moving forward, not to mention the associated costs.

Another challenge when working with high protein concentrations are potential interferences caused by aggregates or the sometimes yellowish, or even brownish discoloration of proteins, observed at high concentrations, which may lead to significant measurement errors if not taken into account.

Solutions for measuring downstream high protein concentrations

The process analytical approach possible with optek instrumentation monitors low protein concentrations using the standard wavelength of 280 nm aiming at the main absorption peak while measuring high protein concentrations off-peak, i.e. at slightly longer wavelengths in the UV spectrum.

In chromatographic processes, a combination of both wavelengths in one dual-channel sensor can be used to track the whole elution process from the lowest protein concentrations required to determine the optimal cut points for fractionation up to the highest protein concentrations present in the elution peak.

In filtration processes, the optimal approach to control a TFF process uses two UV sensors to monitor high protein concentrations in the retentate at an off-peak wavelength to verify the retentate concentration target, and low protein concentrations in the permeate at the peak wavelength with the highest sensitivity to supervise the membrane integrity. As an additional benefit for all retentate measurements, using optek’s dual-wavelength sensor AF46-VB with its secondary wavelength allows compensating for any potential background interferences.

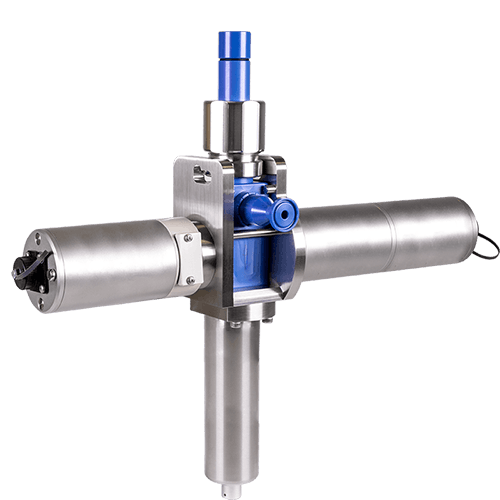

An optek fully assembled SUC27 with an AF46-VB dual wavelength UV sensor. This compact assembly measures two UV wavelengths, pH, conductivity and temperature.

optek solutions for downstream process monitoring

optek offers a variety of UV sensors suitable for both, conventional stainless steel and single-use setups, specifically developed for protein purification, concentration, and formulation processes that require real-time protein concentration measurements at extremely high concentrations of up to 500 mg/mL (approximately 500 OD) or at trace protein concentration levels to provide real time information on:

- Peak protein concentrations during chromatographic elutions of protein fractions

- Retentate concentration target for TFF filtrations and separations, as opposed to conventional TFF methods based on off-line lab measurements, flowrate/volume calculations, or simple time-based process control

- Membrane integrity by monitoring trace concentrations of the target molecule in the permeate

- Data records of the entire production lot in fill stations and formulation areas

As a result, this instant process feedback saves time and money as it reduces manual sampling and increases product consistency and throughput from making process adjustments on an as-needed basis.

In addition all systems are available with optek’s advanced six-electrode four-pole conductivity measurements (0 – 10 µS/cm to 0 – 850 mS/cm), inline pH (0 to 14 pH) and NIST traceable calibration filters.

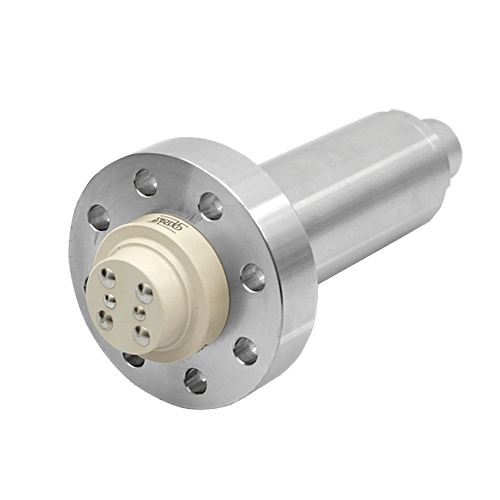

An optek AF45-VB single wavelength UV sensor with a Calibration cuvette installed on a conventional stainless steel sensor body.

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.