Optimizing Color and Turbidity Control in Sugar Refining

In a sugar refinery, multiple steps are undertaken to convert raw sugar to pure “granulated” sugar. Within these steps, opportunities present themselves where automatic monitoring of certain parameters allows the real time ability to optimize manufacturing performance; ensuring the highest product quality and the greatest overall yield.

optek Products used in Color and Turbidity Control in Sugar Refining

In a sugar refinery, multiple steps are undertaken to convert raw sugar to pure “granulated” sugar. Within these steps, opportunities present themselves where automatic monitoring of certain parameters allows the real time ability to optimize manufacturing performance; ensuring the highest product quality and the greatest overall yield.

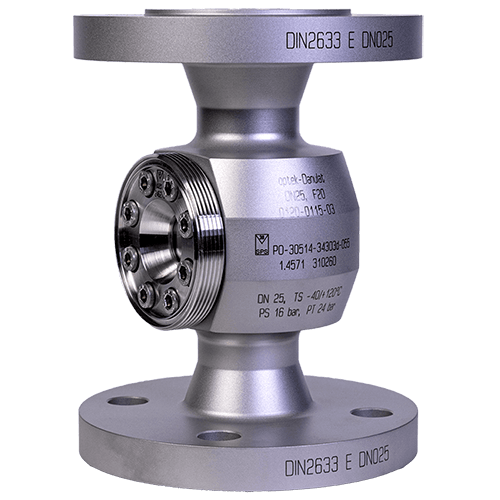

The sugar liquor that results from dissolving the washed sugar crystals in water will still contain some solids, color, and other impurities that needs to be removed. So after adding a coagulant, the sugar liquor is passed through pressure leaf filters to remove the remaining solids from the liquor. Therefore by installing a TF16N scattered light sensor at the outlet of the leaf filters, the sugar liquor stream can be monitored in real time to ensure filter performance and alarm when there’s a filter break.

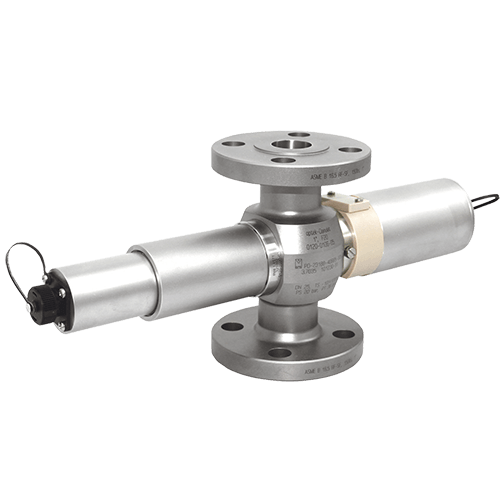

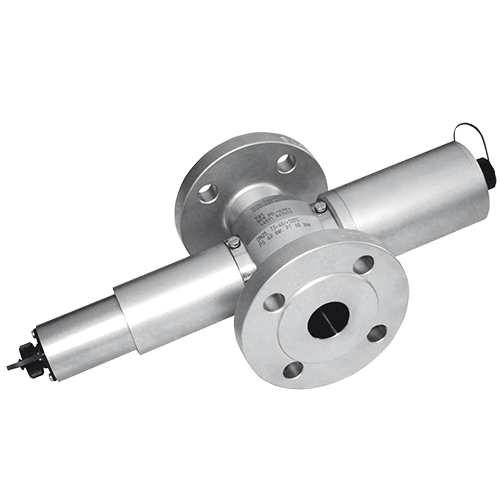

The resultant filtered sugar liquor is then passed through columns of granulated activated carbon (GAC) to remove the liquor’s color, for in general; the less color the liquor has, the better its quality. Further, ICUMSA has standardized the method for measuring sugar liquor’s color, incorporating a number of parameters into its determination. So by installing an AF26 dual beam absorption sensor after the GAC column, it is possible to measure the outlet sugar liquor’s ICUMSA color, providing real time monitoring of the color removal process. And because the AF26 sensor can be configured to specific wavelength combinations and use long optical path lengths, even the slightest ICUMSA color changes will easily be detected.

Benefits of Color and Turbidity Control in Sugar Refining

- Optimization of the clarification process

- Immediate detection of filter breakthrough

- Real-time color monitoring of sugar liquors

- Optimization of the decolorization process

- Syrup blending control

An advanced C4000 converter allows two sensors (AF26 color and TF16N turbidity) to be used simultaneously to save costs and installation/maintenance efforts.

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.