Natural Gas Liquids (NGL) Color Monitoring

Natural gas liquids (NGLs) and petroleum condensates are mixtures of light end, liquid hydrocarbon fractions that are manufactured during refining, or collected as they emerge from oil & gas fields. One of the indicators of product quality will be the color of these streams, where increasing amounts of “yellowness” indicate more and more carryover of undesirable heavy hydrocarbons fractions. The norm ASTM D156 defines acceptance criteria of the product quality of these hydrocarbon streams based on the Saybolt color scale.

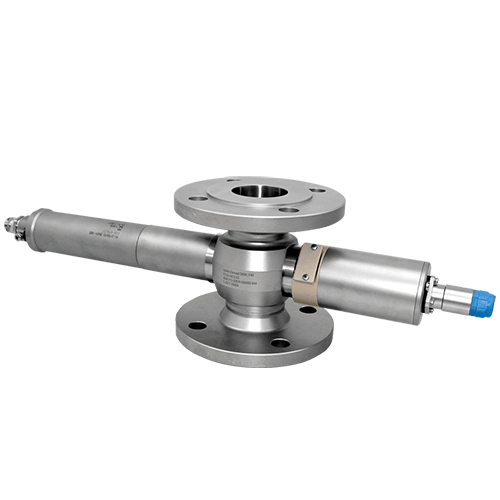

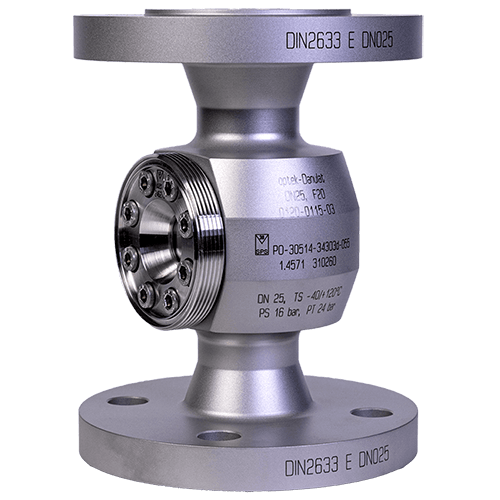

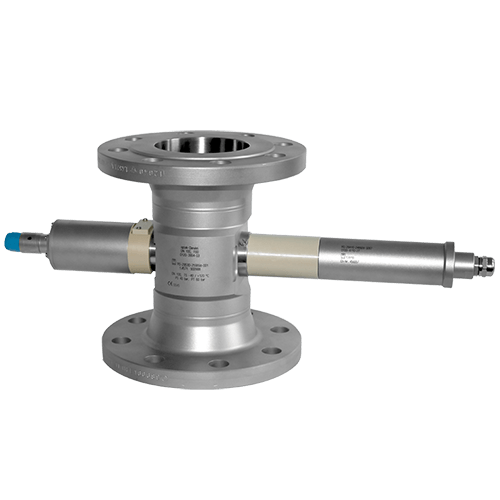

optek Products used in Natural Gas Liquids (NGL) Color Monitoring

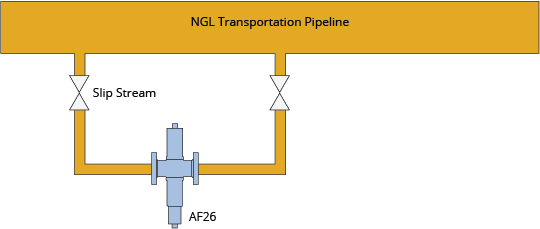

Because of the pressurized nature of NGL streams, manual testing for Saybolt color requires conditioning of the sample before the color can be determined, a dangerous and often inexact process. However, optek has designed process connections that allow for Saybolt color to be monitored in real time, under high pressure process conditions – eliminating the need for any sample handling. Therefore, refinery and pipeline operators can make instant decisions based on real time Saybolt color measurements.

There are three main areas where NGLs and petroleum condensates are monitored for color changes. First, where NGLs and condensates are transported to unloading stations, it can be controlled by real time monitoring of Saybolt color, whether the truckload (or portion of the truckload) can go directly to storage for sale, or whether it needs to go for further refining. During the refining process, real time color determination is used as an indicator of product quality, or to indicate when an upset has occurred in the refining process (i.e. amine leak). Finally, Saybolt color is monitored as part of the transfer of NGLs from producer to pipeline owner, typically installed as one of the measuring systems on LACT skids (Lease Automatic Custody Transfer units).

Natural Gas Liquids (NGL) Color Monitoring Benefits

- Real time monitoring of NGL quality

- Verifies product color during custody transfer

- Can be installed in very high pressure process streams

- Can be installed in any electrical area class

- Eliminates sample handling & conditioning

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.