Turbidity of White Water

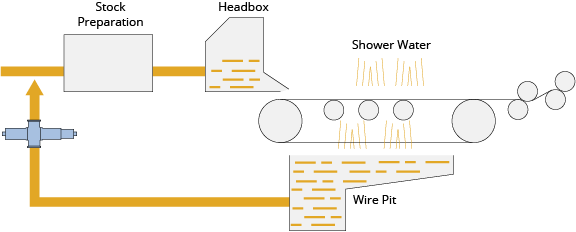

White Water QualityIn the sheet-forming step of papermaking, excess water from the dewatering process is called white water. Significant economical and environmental benefits can be realized by optimizing the efficiency of the paper making process.

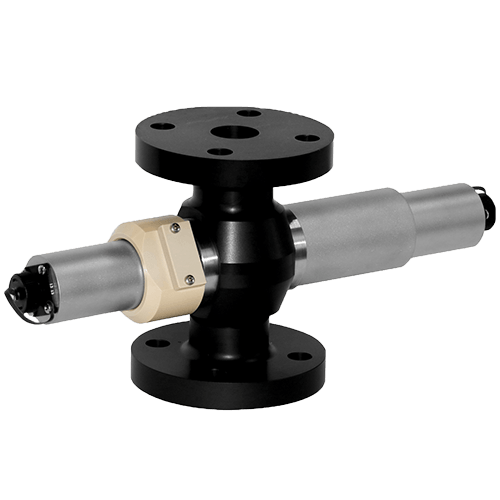

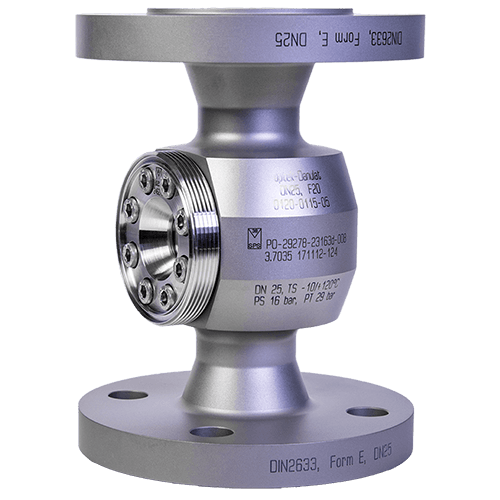

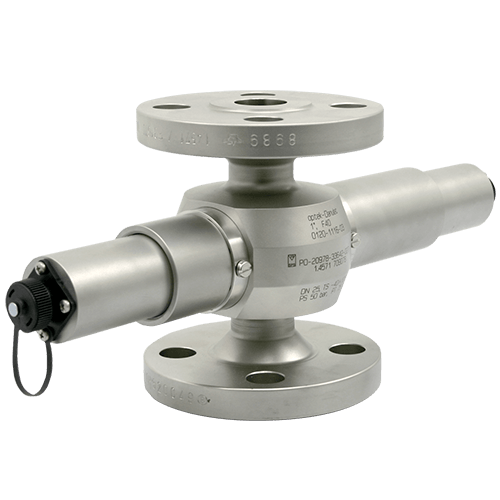

optek Products used in Turbidity of White Water

While the majority of the pulp fibers are retained on the paper machine clothing (wire mesh web) forming the paper web, the remaining pulp stock and water fall through and are collected in the white water tank. Monitoring the concentration of this white water using an optek AF16-N Near-Infrared absorption sensor may provide paper mills real-time information on the efficiency of the mesh web.

Chemical Feed Control

In an effort to conserve and reuse mill process water, white water from the paper machines is typically sent through DAF units or other separation devices in which the remaining fibers and solids are removed by the addition of chemicals and/or flocculants. Using an AF16-N sensor for constant inline monitoring of the solids/turbidity before and after a DAF unit, the proper chemical dosage can be automatically controlled, allowing for chemical optimization, a consistent post treatment water quality and mill wide water use reduction.

Benefits

Waste treatment cost savings are realized by the recovery of usable fiber and fillers normally sent to a landfill or sewer. Also, by controlling particulate levels, energy consumption is reduced.

optek AF16-N Single Channel Absorption Sensor

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.