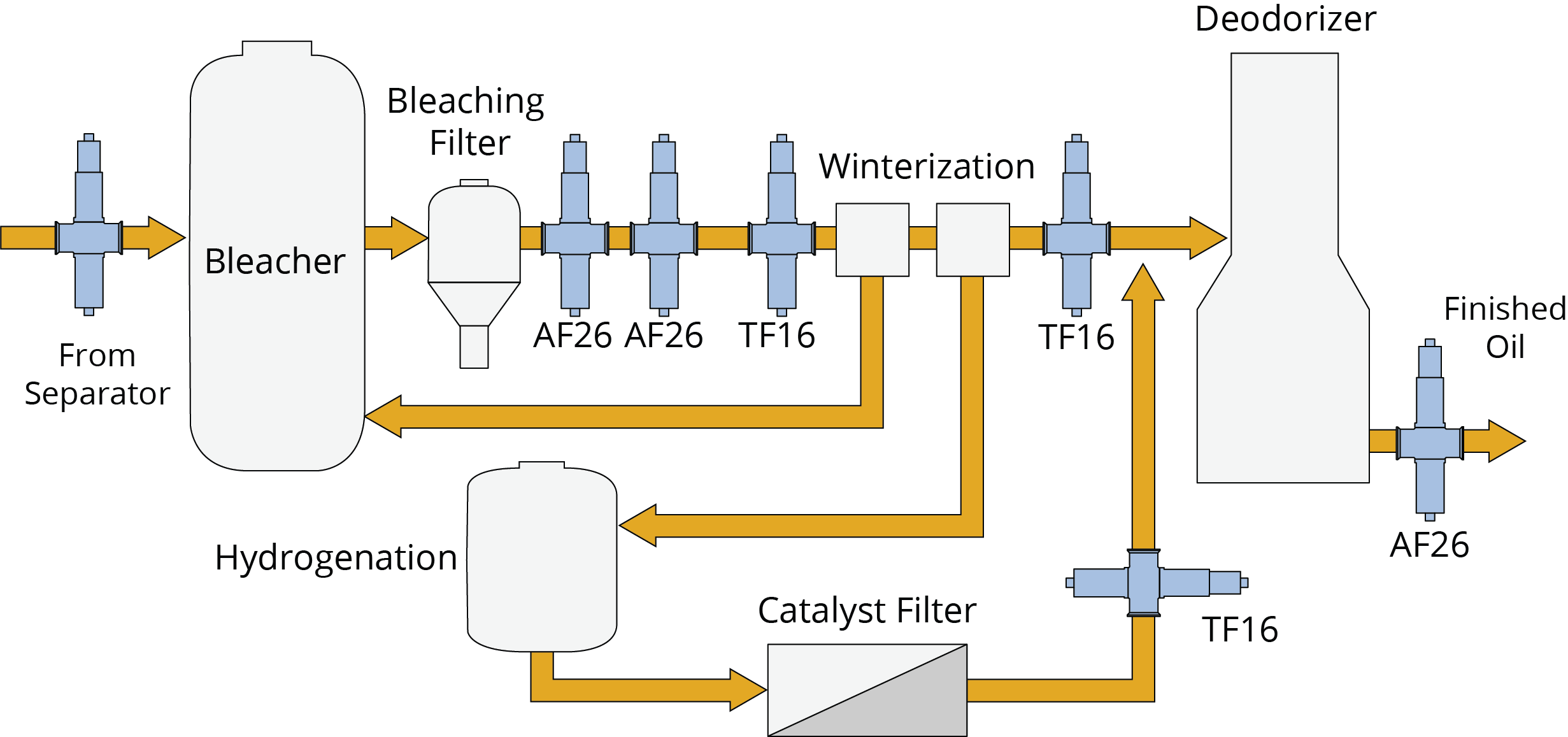

Vegetable Oil Refining Process

Monitoring oil refining processes such as winterization, bleaching, hydrogenation, and finished oil quality in real time can be greatly improved with the use of optek inline colorimeters and turbidimeters. Out of spec product is immediately detected allowing process adjustments to be made quickly, avoiding costly product reworking. optek inline sensors not only deliver reliable and precise results but are also designed to withstand the harsh conditions in oil refining including high temperatures up to 240°C.

optek Products used in Vegetable and Edible Oil Refining

Vegetable Oil Refining Benefits:

- Improve Vegetable and Edible Oil Quality

- Reduce Bleaching Clay Usage

- Conserve Nickel Catalyst

- Continuous Process Control

- Eliminate Human Interpretation Errors

- Exact Dosage of Used Supplements

- Timely Intervention at Process Changes

- Reduced Product Loss

- Higher Product Yields

Using optek inline colorimeters and turbidimeters throughout the vegetable and edible oil processing minimizes sampling and timely lab testing, while recording measurements inline and in real-time. Operating costs are greatly reduced due to reduced losses, downtime, and reworking. optek inline measurements can improve filtration throughput, reduce re-circulation time and reduce usage of filtration agents like bleaching clay and nickel catalyst.

Color Measurements for Quality Control

Color measurements are important both after the bleaching and filtration processes and as a final quality check after deodorization just prior to tank storage. The optek dual channel AF26 colorimeter’s output can be correlated to almost all color scales including AOCS, APHA and Hazen. Inline measurements provide process control of the refining and bleaching processes.

Bleaching and Filtration

The bleaching process can be optimized very effectively using optek colorimeters. Monitoring the color after the bleaching filter is the key to controlling the addition of bleaching clay. Thereby the filtration process can be automatically set to a recycle mode until the desired clarity is achieved. Additionally, filtrate monitoring will immediately detect filter breaks and track filter performance – an excellent tool for quality assurance and quality control.

Control of Chlorophyll Concentration

The concentration of chlorophyll varies in oilseeds. Large amounts of chlorophyll reduce the shelf life of vegetable and other edible oils. Oils with higher concentrations of chlorophyll generally require an extra processing step where the oil is heated to break down the chlorophyll. Monitoring oil in the pipeline before it is sent to the bleaching process allows the highly concentrated chlorophyll oil to be diverted through the extra heating process while oil with a low concentration of chlorophyll moves into the bleaching process. The optek dual channel colorimeter AF26 is capable of measuring chlorophyll concentrations < 30 ppb (parts per billion), all in real-time and inline with high precision and repeatability.

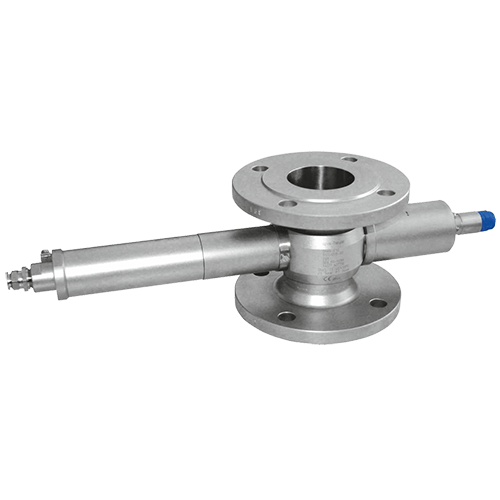

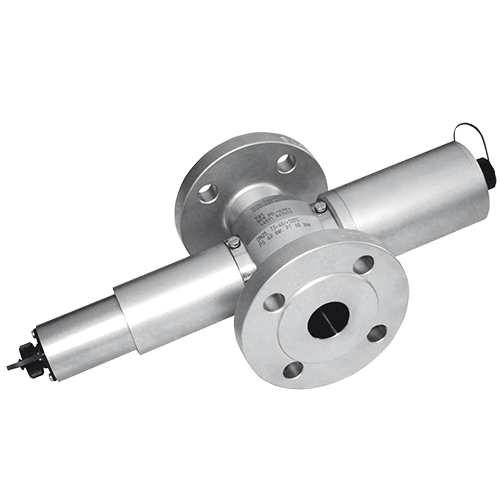

AF26-VB

Winterization

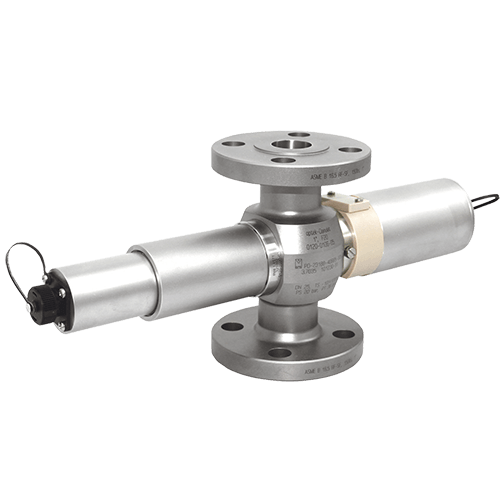

The winterization process for edible oils serves to remove high melting components like wax from the oil. Installed directly inline following the winterization process, an optek TF16-N scattered light turbidimeter can provide real-time monitoring of the performance of the process. Any remaining high melting components (such as waxes) can be immediately detected and measured down to low PPM ranges and thereby greatly reduce losses due to rework of out-of-spec product.

Hydrogenation

Hydrogenation of oils applied in the production of solid fats and margarine is required to give the finished oil a higher melting temperature and better oxidation stability, improving the product’s resistance to spoilage. Generally, nickel-based catalysts are used in this process. Once the hydrogenation is complete, the nickel catalyst must be filtered off. Filtering off the catalyst can be controlled by an optek turbidimeter TF16-N capable of detecting very low catalyst concentrations, thus reducing the loss of nickel catalyst and optimizing the filtration process while ensuring final product quality. An ATEX/FM version of the turbidimeter is available for installation in hazardous areas.

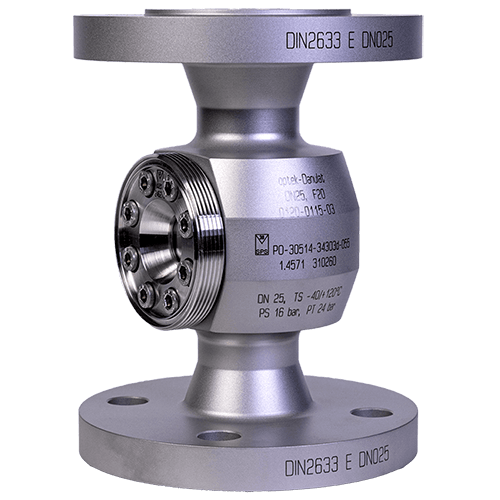

TF16-N

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.