Beer Filtration Control 11° / 90°

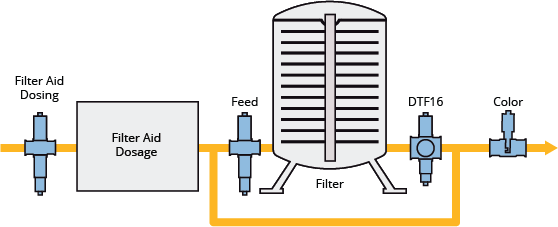

The optek Haze Control / DTF16 relies on a dual angle, scattered-light measurement for precise quality control during final beer filtration independent of color and color changes. Using this sensor downstream of the filter monitors filter performance, preventing “out of spec” product while ensuring beer quality and clarity at each filtration step. The 11° channel is sensitive to particle size change and immediately detects break through and other non-normal turbidity events, while the 90° channel quantifies the visual clarity for quality assurance.

optek Products used in Beer Filtration Control 11° / 90°

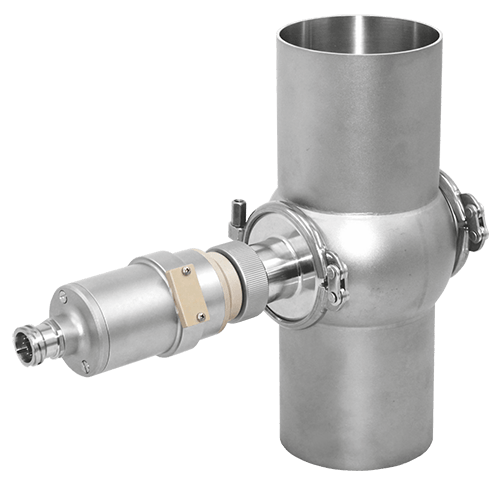

Filter Feed Line Monitoring

Using an optek AS16-N or AF16-N, the turbidity in the feed line can be monitored, allowing precise feed control while preventing filter clogging or blinding. Optimized body feed rates has tremendous impact on filter throughput capacity. This additional sensor can be connected to your Haze Control / DTF16 system without the need for an additional converter.

Filter Backwash Optimization

The optek AS16-N or AF16-N used for feed monitoring can also be used to optimize your filter backwash process by measuring the turbidity in the water, saving time, energy and conserving water usage.

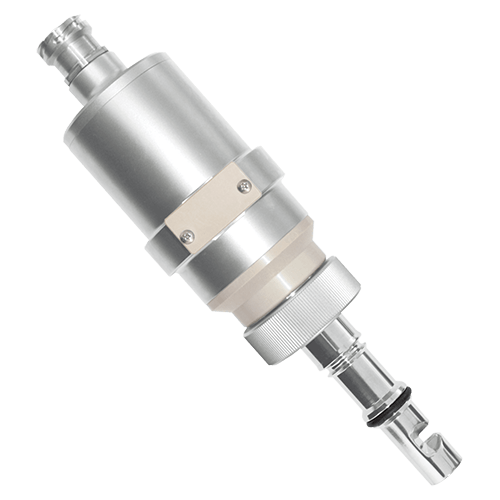

optek DTF16 Process Turbidimeter

Filter Aid Dosage

Dosage of filter aids like Kieselguhr or PVPP can be controlled with optek absorption or turbidity sensors. Optimizing filter aid usage can dramatically increase throughput capacity and recovered product, and reduce down cycles and costs, all while ensuring consistent product quality.

Beer Interface Detection

The Haze Control / DTF16 system may also be paired with an AS16-F or AF16-F to measure the color of your beer. This measurement controls the phase separation between beer and water ensuring faster product changeovers while maintaining product quality and minimizing product losses.

Filter Setup Monitor

Using the 0° absorption channel of the sensor DTF16, turbidity up to 500 EBC can be measured, allowing you to monitor and control the filter pre-coat cycle. This provides an additional opportunity for filter optimization.

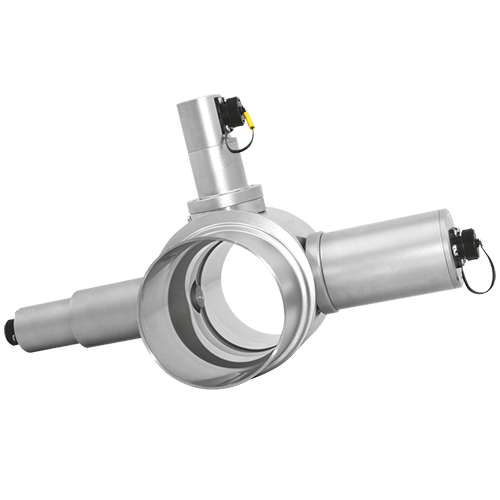

optek Haze Control

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.