ASBC / EBC Beer Color Measurements

Beer Color is ImportantThe use of precision colorimeters before the fillers can provide beer color dosing control and quality control based on specific color aspects of the brands. Single or dual beam colori-meters configured to monitor specific visible wavelengths can offer continuous inline monitoring to minimize sampling and lab analysis. A consistent visual impression for the end customer is as important as the possibility for product identification.

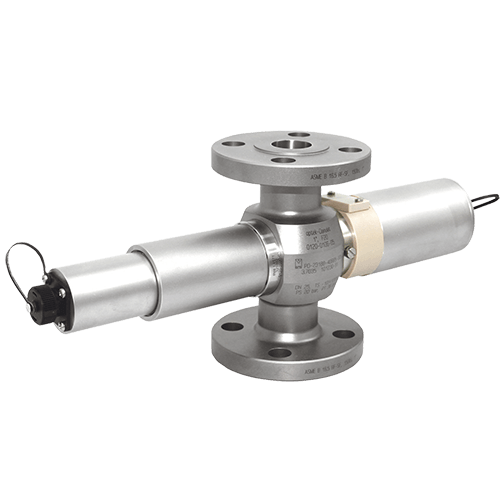

optek Products used in ASBC/EBC Beer Color Measurements

Wort Color

Wort color is also measured using absorption. However, beer color is measured using visible light (VIS) at 430 nm. In the brewhouse this poses a problem as background turbidity (solids) will also absorb light at 430 nm. To compensate for this, optek measures at two wavelengths, one at 430 nm and a second reference wavelength in the near infrared (NIR).

Subtracting the absorbance signal of the reference channel from the primary, visible channel signal gives a pure beer color measurement. This result is then correlated to ASBC or EBC color scales using the software features of the C4000 photometric converter. The optek AF26, dual channel absorption based colorimeter is ideal for this application. Simultaneously, the reference channel can monitor trub and cold break if the AF26 is strategically located after the wort cooler.

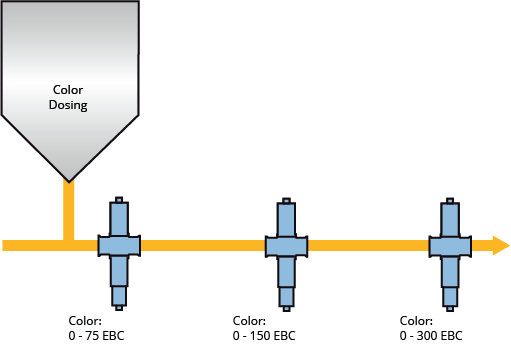

Beer Color Dosing

The color of some beers will be adjusted using malt extract or rye malt beer for example. Dosage can be controlled using an optek colorimeter. The color of the beer is measured and automated signals i.e. relays, 4-20 mA analog signals, or Bus Systems, can be used to trigger pumps or drive control loops to start and control dosing the color into the beer stream. After the dosage, the color can be verified by a secondary colorimeter. Color of dark and bright beers, as well as the color of high gravity beer after blending can all be controlled.

Beer Interface Detection / Beer Phase Separation

Precise process interface detection with a single channel VIS absorption based colorimeter (insertion probe style) is the easiest and least expensive technique available to brewers today to reduce product losses. The AF26 performs this function as well. In a large brewery, the sheer number of change-over operations per day can cost the brewer thousands of hectolitres of product and by-products each week.

Optical photometers provide an immediate response to beer phase separations (change-overs), saving as much as seven seconds per transition over other sensor technologies. In some cases, the water pushout sequence can be reduced from flushing the entire pipeline to simply introducing a small amount of water between brand changes or even eliminating the water step entirely by directly sensing the change in brand color.

In today’s economy, recovering this product is essential to maintain a profitable business; however, the costs go beyond the product alone. Water as the push-out medium is also a commodity and has an inherent cost to procure and treat. Product and water, along with yeast, going needlessly down the drain are large contributors to brewery waste / plant effluent and the costs to treat it. Local municipalities may also be involved; applying charges to the volume of effluent and even fines if solids load or BOD limits are exceeded. Gaining control of plant interface functions not only makes sense, it’s also environmentally friendly. All of these factors contribute to lower costs per barrel and assure consistent product quality.

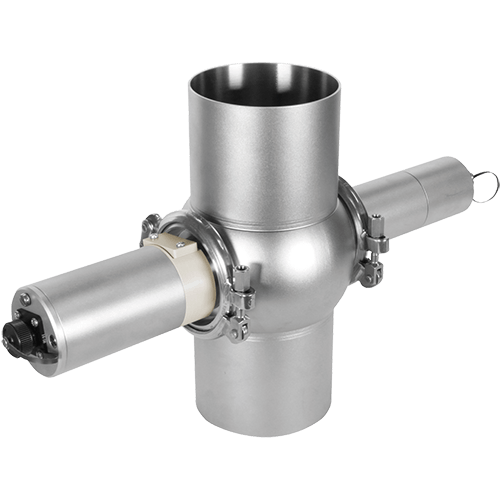

optek AF26-VB-PV Dual Channel Absorption Sensor with Calibration Adapter

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.