Inline Chlorine Dioxide Monitoring

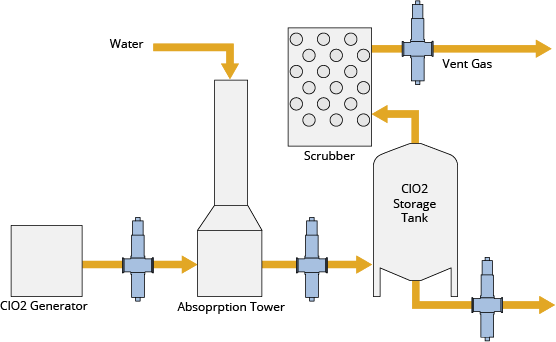

Inline ClO2 MonitoringChlorine dioxide (ClO2) has become the most significant bleaching agent in the pulp and paper industry for Elemental Chlorine-Free (ECF) bleaching. Different bleaching sequences must be used in the production of various pulps. This depends on the pulping process used, the residual lignin content of the pulp, and the target brightness. Key goals at most pulp mills include the optimization of reaction efficiency of ClO2 generators, the proper dosage of ClO2, and improving the control of vent-gas scrubbers to reduce chlorine dioxide emissions into the atmosphere.

optek Products used in Chlorine Dioxide Monitoring

Chlorine dioxide gas is commercially generated either by reduction of sodium chlorate in an acidic medium or oxidation of sodium chlorite. It is a synthetic yellowish-green, explosive gas, which is stable as an aqueous solution only if the solution is protected from light and kept refrigerated. For this reason, chlorine dioxide must be produced and consumed onsite by means of a chlorine dioxide generator. The efficiency of these generators and the dosage of chlorine dioxide can be optimized using optek inline ClO2 analyzers.

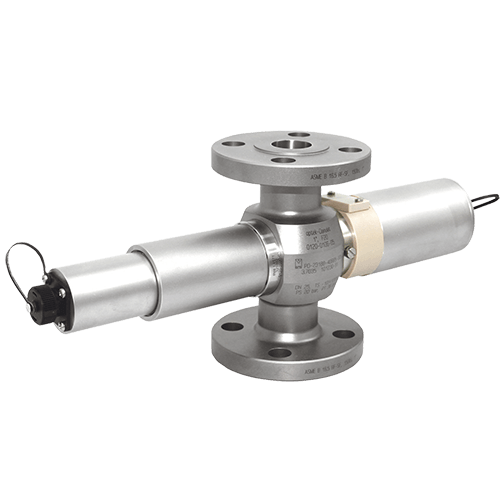

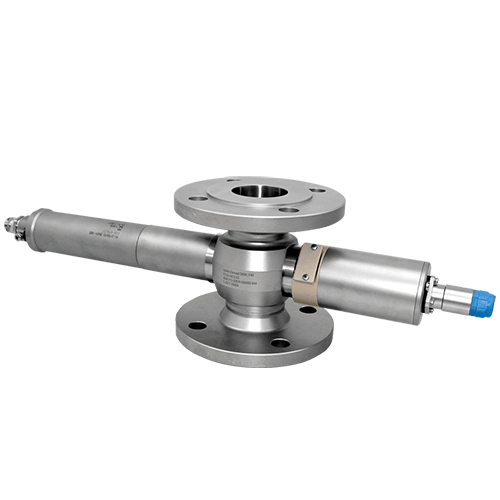

Due to the very aggressive nature of the process stream, all wetted parts are manufactured from corrosion resistant materials, such as titanium and sapphire. Integrated dual-channel reference detectors compensate for all possible disturbances such as varying levels of particulates (turbidity) and lamp aging. Special NIST-traceable reference filters allow users to verify analyzer performance without any process intrusion, making validation quick, simple and safe.

Installation

optek sensors are easily installed to provide real-time measurements that optimize process performance. The modular optical design ensures optimal installation and high resolution measurements.

optek AF26-EX-VB Dual Channel Absorption Sensor

Benefits

optek provides inline, real-time analyzers designed for industrial pipelines. These sensors are installed using flow-through sensor bodies that can withstand high pressure installations. Sampling from the process stream and laboratory analysis are no longer needed due to the inline concentration measurement directly in the pipeline.

Inline ClO2 concentration measurements are achievable in liquid and gas streams. Split-beam technology compensates for lamp aging and varying particulate levels including bubbles.

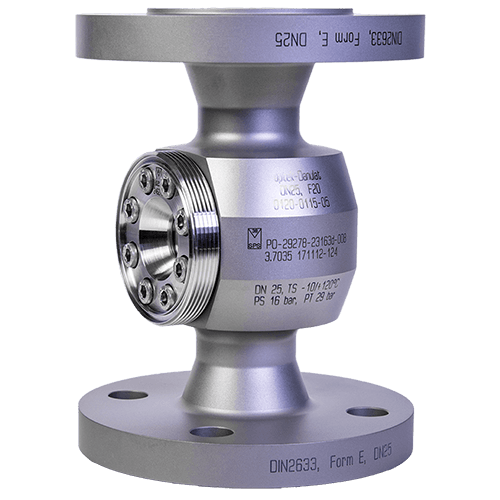

optek C4000 Photometric Converter

The signals from other instruments measuring temperature and/or pressure are recommended to be used directly as compensation for the raw gaseous ClO2 concentration. optek inline sensors are also available with hazardous area classifications (ATEX, FM).

Use of special materials such as titanium and sapphire offer excellent resistance to all abrasive and corrosive media and ensure longevity of the installation. To reduce installation costs in multiple point applications, the microprocessor based C4000 converter with four 4-20 mA outputs is capable of interfacing with two separate inline sensors. The signals of the converter can optionally be transferred to a PLC or plant DCS using the PROFIBUS® PA communication or FOUNDATION™ Fieldbus.

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.